The global energy system is undergoing a momentous transition that is reshaping our policy landscapes, spurring new technologies, and disrupting business models. The emergence of low-carbon or carbon-free fuel alternatives and the proliferation of CO2 capture technologies inherently rely on smarter ways for storing such at required volume and pressure, if we are to decarbonize our industries quicker and more efficiently.

Explore our solutions for Maritime decarbonization the Carbon Capture Utilization & Storage (CCUS) value chain and Green mobility.

Key Facts

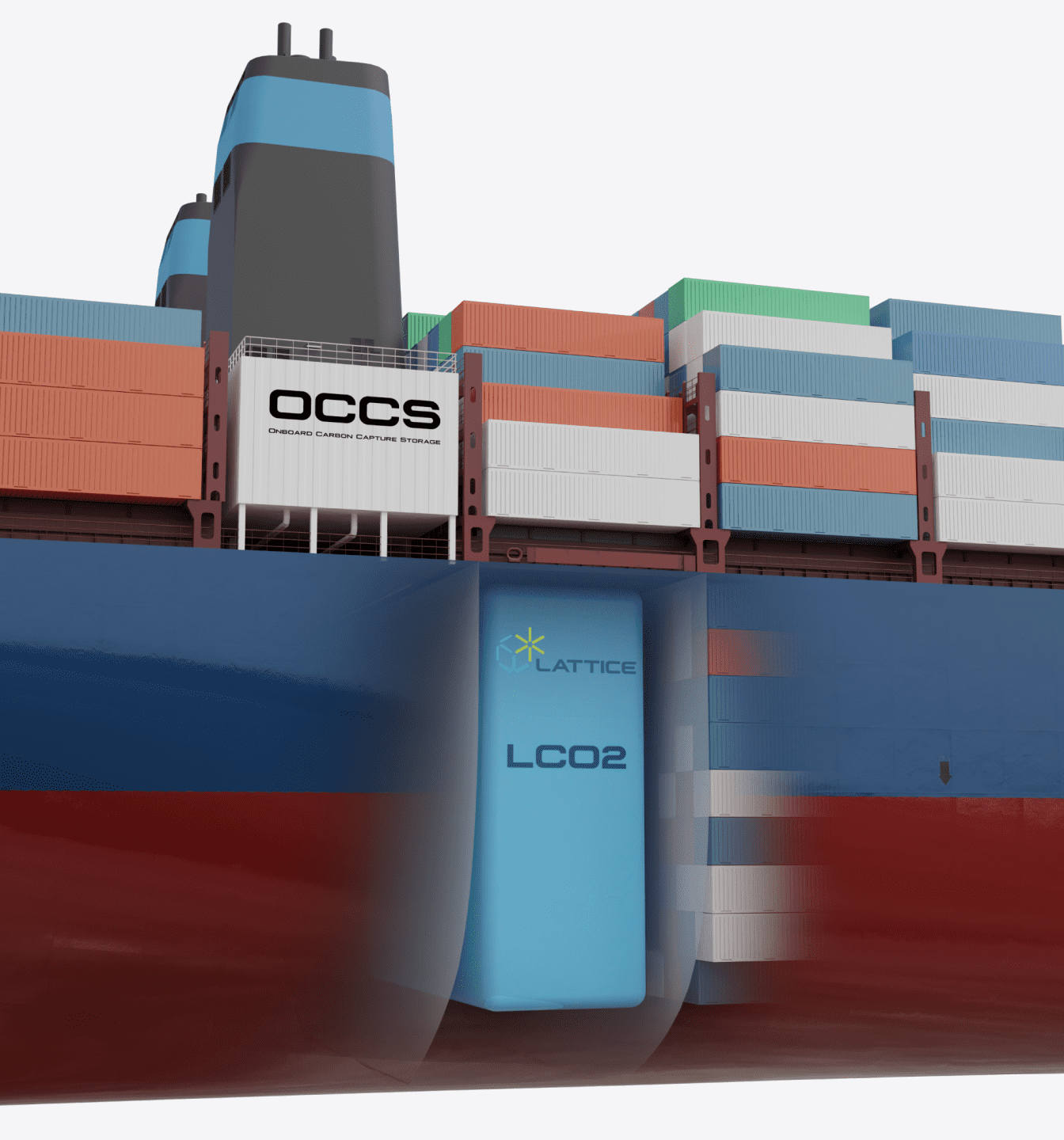

The entire maritime industry stands mid-ocean in a sea of changes that are impacting operating models, sustainability performance, savings, and revenue streams, and most importantly, company bottom lines. Onboard Carbon Capture & Storage (OCCS) represents the fastest and most cost-effective way per date to decarbonize your fleet. By installing an OCCS processing unit and an optimized CO2 storage tank, you won’t have to bet on an alternative fuel or wait for associated infrastructure to reach critical mass in order to be economically viable – rather you can rely on existing infrastructure and economies of scale to facilitate your carbon reduction targets – reliably, measurably, immediately.

Case examples for:

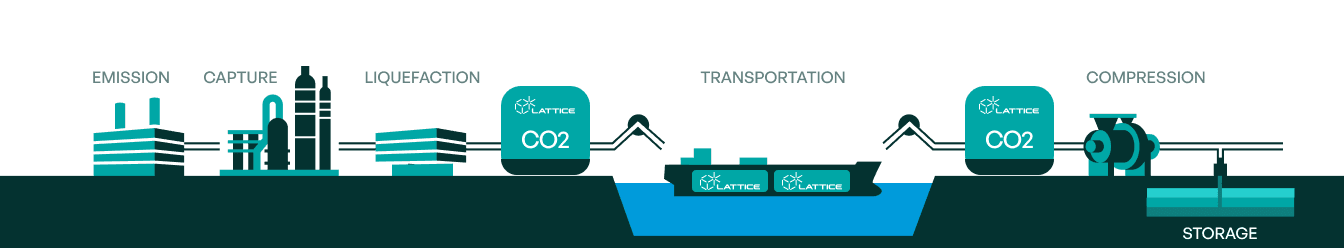

Liquid CO2 (LCO2) is a dense yet changeable substance that imparts specific challenges on part of the containment solution, both in terms of the pressure rating and subsequent temperature regime under which it is stored. This implies being able to cater to the triple point conditions in a safe and cost- effective manner. Numerous factors play in when designing optimized LCO2 tanks, especially when having to cater to varying operating conditions and criteria. The inherent flexibility of the LPV technology allows us to realize the leanest and lightest tank designs, thereby ensuring the lowest cost for our clients’ projects.

The LPV helps bring about synchronicity between the various stages. Smarter interchange and operability and improving economy of scale will ultimately be crucial for lifting the entire LCO2 value chain. This includes intermediate storage of captured LCO2 at the emission site; large-scale tank solutions for storing LCO2 at terminals and onshore installations; optimized LCO2 cargo tanks for transportation per ocean-going carriers; barges and floating storage solutions that cater to the regasification process and/or injection of CO2 into the final well or deposit site. LATTICE works with global leaders at the forefront of developing the CCUS sector to provide complete turnkey solutions for the benefit of our end clients.

Case examples for:

Hydrogen energy carriers are expected to play a key role in our future transport systems: as an energy carrier, fuel source and feedstock. Handling these liquefied gases imparts a particular set of challenges upon the containment solutions due to their cryogenic temperatures, pressures, and procedures for keeping hydrogen in constant liquid state. LATTICE not only provides the optimal technology for storing and adapting your NH3 or LH2 fuel- or cargo tank to any space or shape. We also provide our clients with a unique, state-of-the-art complimentary vacuum insulation system for minimizing losses during transportation or storage.

Case examples for:

Approved by ASME, all major Classification Societies, US Coast Guard