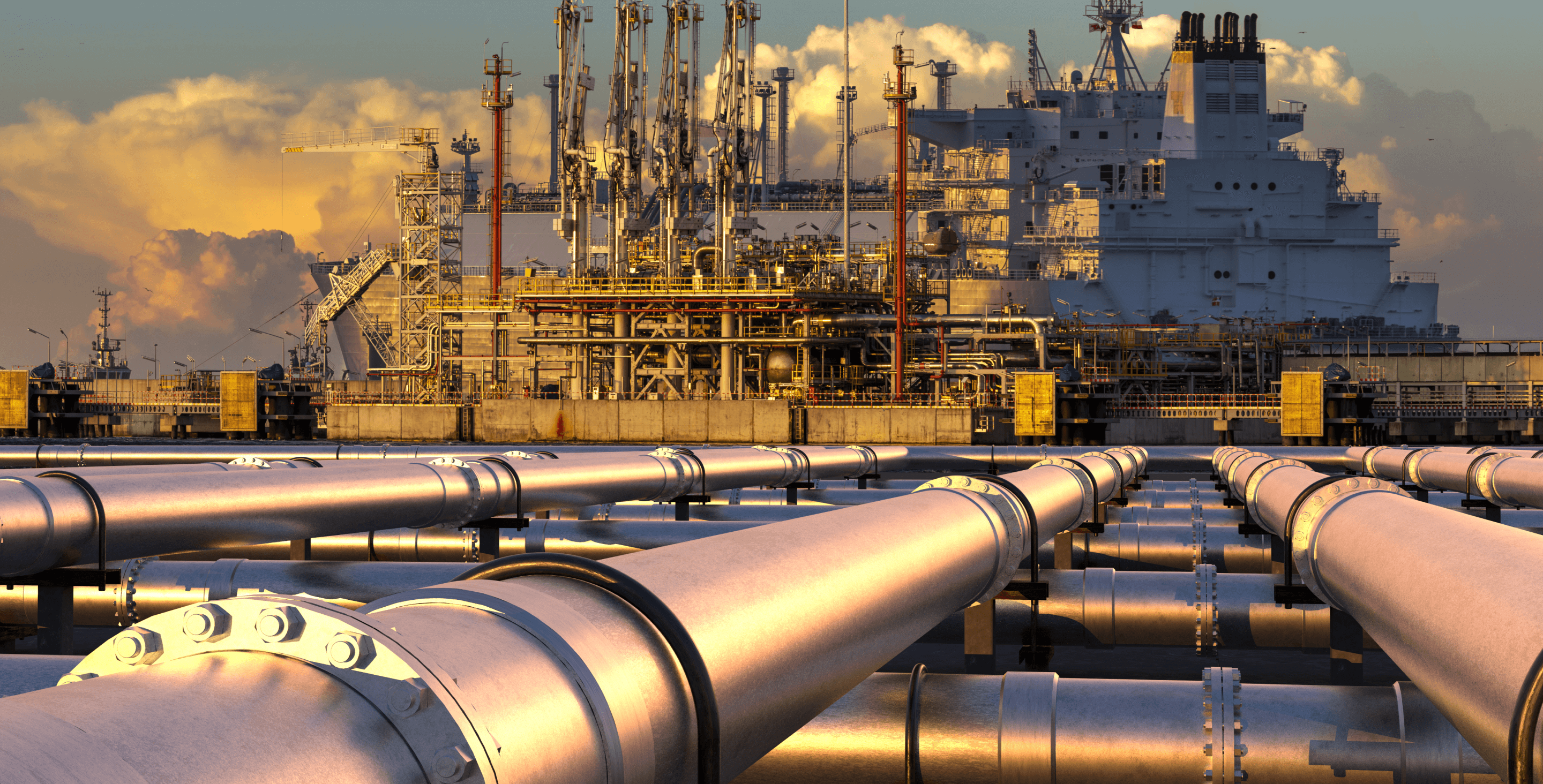

Energy infrastructure constitutes the critical backbone of our energy systems. It’s a complex network where all the components of the value chain must function and connect seamlessly between suppliers and consumers. This pertains also to the global provision of gases, whether for power generation, industrial processes or distributing fuels for transportation: at every step throughout the entire supply chain you need to be able to store gases effectively en masse – whether it be within dense industrial clusters, confined manufacturing sites, or bespoke floating units operating offshore.

Explore our solutions for Floating units and Onshore containment systems for Manufacturing sites.

Key Facts

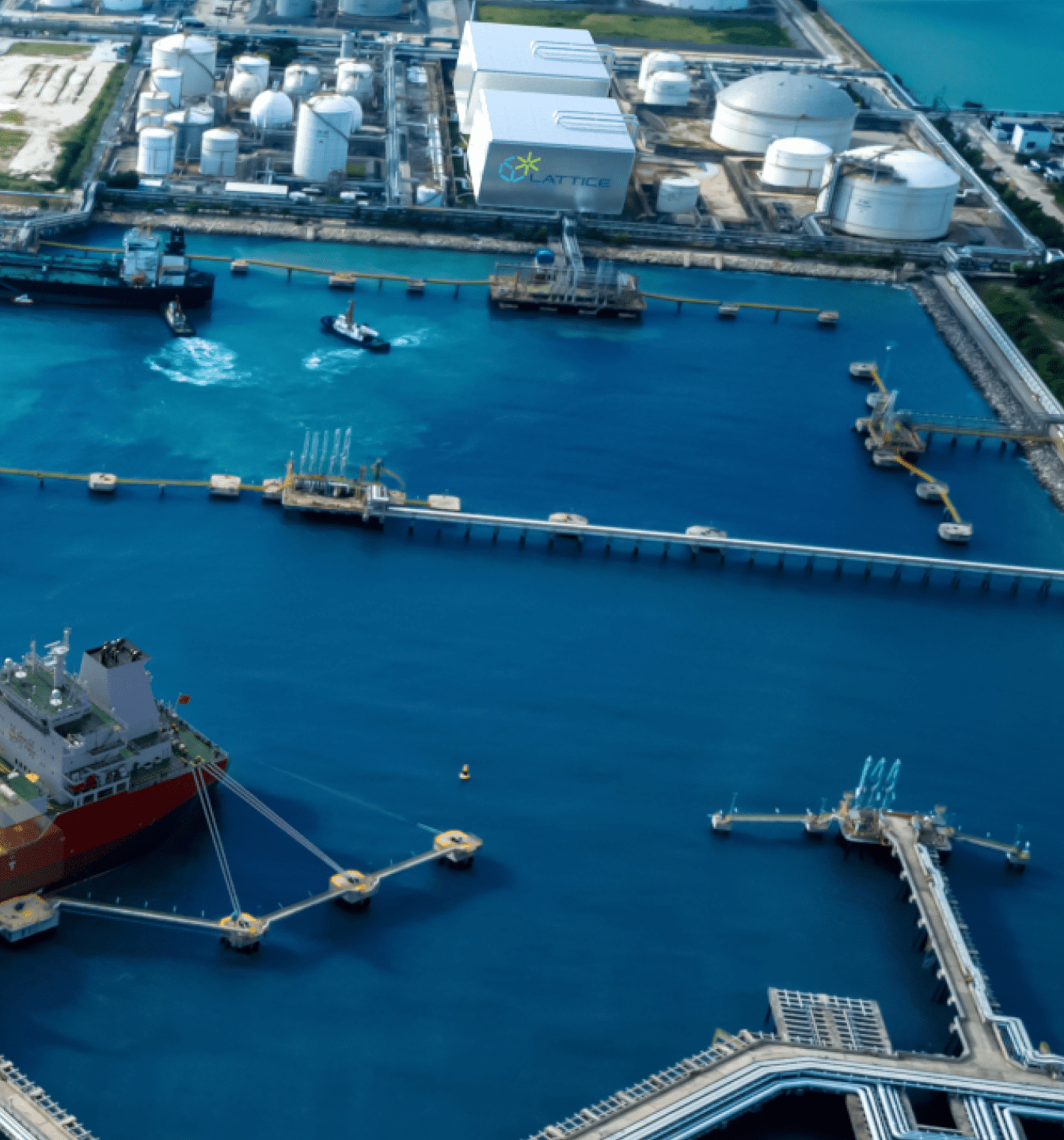

Floating installations are large productions units operating offshore or near shore for the purpose of handling, processing and storing immense amounts of liquefied gases. These are complex and expensive hardware units where topside equipment is directly impacted by the storage capacity and efficiency obtained in the hull below. Hence, simplification, scalability, and safety are paramount for safeguarding operations and economic viability of floating storage projects. Whether for regasification/liquefaction of LNG or injecting CO2 back into deposits underneath the seabed: our LPV tanks are unlocking new savings potentials and operational benefits for accommodating your floating installations with smarter, more compact containment solutions.

Case examples for:

Handling large quantities of liquefied gases requires large-scale storage systems to facilitate quantities and synchronize deliveries in accordance to demand. Onloading and offloading terminals provide one such crucial interface for ensuring effective distribution flows. However, these hubs are faced equally with space limitations for meeting new volumes, which will only grow in tandem with the ongoing energy transition. We work with EPCs, industrial site managers and terminal operators to design and configure the optimal storage units, whether for mature applications such as LNG, or for emerging fuels such as NH3 or LH2, or accommodating the tremendous amounts of captured LCO2 to be facilitated back upstream through a reversed distribution system – from emission point to well.

Case examples for:

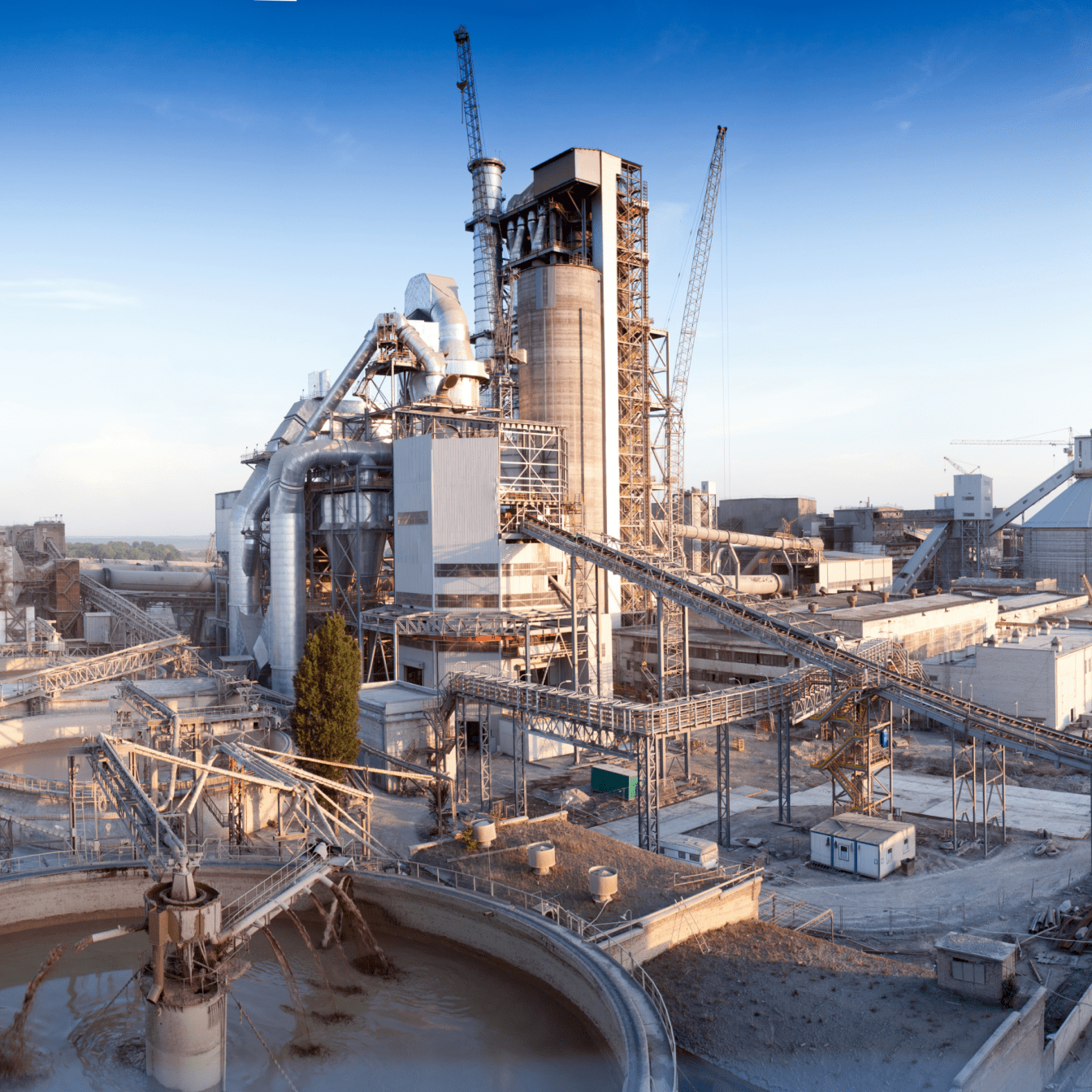

Manufacturers within hard-to-abate industries are faced with an unprecedented pressure to shift and decarbonize their operations. Nowhere else than in Europe are these pressures more evident, manifesting in new operating procedures and performance standards adopted at production sites, all the way to companies’ bottom lines. LATTICE offers, for instance together with carbon capture technology providers, optimized solutions for storing LCO2 at emitter sites without disrupting other core activities. Moreover, we provide opportunities for storing energy carriers like liquid H2 at bulk scale at energy intensive sites, whether you have a steel mill or chemical plant requiring feedstock for manufacturing processes.

Case examples for:

Approved by ASME, all major Classification Societies, US Coast Guard