No industry epitomizes global trade and economic interdependence more than the container vessel sector. From the smallest feeder vessels operating between ports and hubs, to the largest mega-size container vessels operating between continents: the defining aspect for all such vessels is the ability to maximize capacity within the ship’s real estate to transport as many containers as possible from A to B.

Today’s global container fleet counts above 5000 vessels, and it is moving steadily from MGO to lower fossil fuels such as LNG, and even other lower carbon alternatives. Until date, pressurized, low temperature fuels like LNG, have relied primarily on cylindrical or bilobe containment solutions for ensuring effective storage before combustion. Their shape have stood at odds with the rest of the ship’s box-like or prismatic configuration, requiring relatively more space, thereby forfeiting a potential for which containers could otherwise be used.

LATTICE provides clients in the container vessel sector an opportunity to change this problem. Case studies we have conducted for customers have demonstrated volume optimization potentials between 20 and 50%, where typically a 30% increase has been seen by switching from a tubular or cylindrical fuel tank to a more compact and space efficient LPV solution. This may in turn result in multiple 100s of TEUs more being freed, thus bearing significant comparative monetary impacts to the client.

The average increase of LPV contra a bilobe for a 10,000 TEU container vessel showed a +113 TEU improvement potential. Depending of course on operating pattern, freight pricing, frequency, duration, and other factors, this comparative improvement could yield +4 MUSD upside in added revenues annually for the vessel operator, and consequently triple digit (>100) MUSD over the total lifetime of the vessel.

Strong value additionalities for feeders, as well as very large container vessels, has been ascertained in our case analysis. As such, implementing a LPV does not only raise the revenue generating capacity and value of the ship itself, but also the value of the companies who own and operate them.

Contact us to see how we can improve your fuel tank performance.

Enhances your vessel’s value by increasing its comparative TEU carrying capacity and revenue generating capability.

Optimize your fuel tank configuration with LPV to ensure the most compact and efficient configuration whilst maintaining volumetric fuel capacity.

Utilization within allocated holding space to increase vessel range, operational flexibility, and minimize downtime.

LPV tanks can be perfectly designed, adapted, and integrated into lower value sections of the ship or underneath the wheelhouse, thus avoiding additional cargo bays or space to be forfeited.

Dual-purpose LPV tanks that accommodate for and ready your vessels for a zero-emission fuel scenario (example LNG fuel tanks that are ammonia-ready).

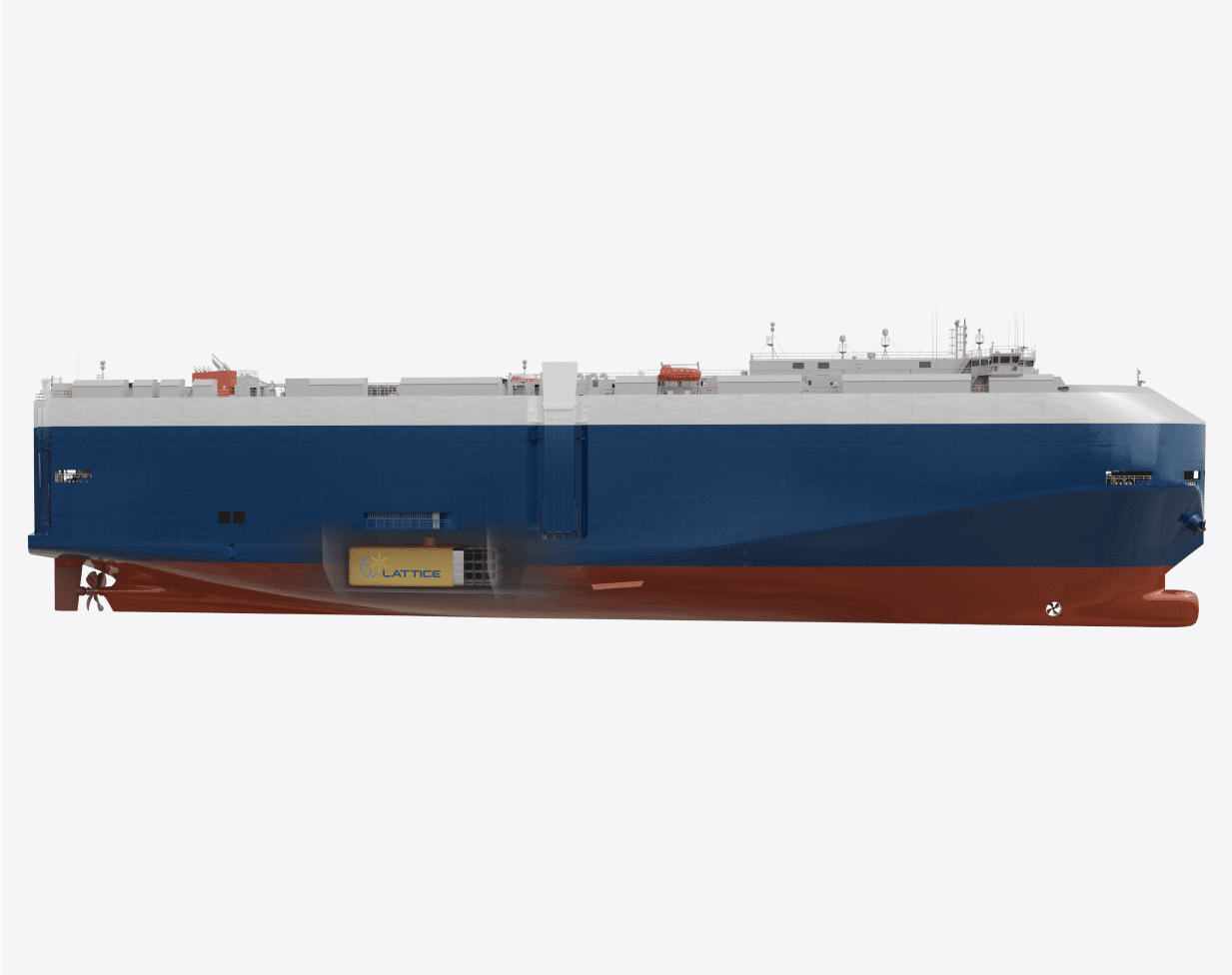

Few ocean-going vessels entail the precision and proficiency required for maximizing available space onboard more than RoRo carriers. RoRo carriers like PCCs and PCTCs are designed for specific cargo types, and different decks contain different types of vehicles or equipment – some more valuable or space-intensive than others. The ability to cater to high value freight such as trucks, buses, heavy machinery, or other non-containerized equipment, typically held in the lower decks, will have an impact to a ship’s earnings per voyage.

Presently near 24M vehicles are transported annually by RoRo carriers; and is poised to continue increasing. Moreover, near all newbuilds feature lower carbon fossil fuels, presently LNG and in the future ammonia, that has significantly lower comparative energy density to that of MGO. This necessitates greater relative volumetric capacity fuel tanks for operating vessels between distances than before. A car carrier operating between continents typically has a 4,000 m3 LNG fuel tank, thus impacting valuable space that would otherwise be used for cargo. Further, fuel tanks can affect space availability potentially over multiple decks within the ship.

LATTICE offers owners the opportunity to enhance and optimize the fuel tank design for their vessels in every dimension, thereby minimizing, if not eliminating, the impact of the fuel tank on decks dedicated to higher value cargo. Tailor-made box-shaped LPV solutions can be integrated effectively into new vessel designs or adapted optimally to existing ship

7,600 CEU PCTC: LPV vs. Cylinder LNG fuel tank

A car carrier’s carrying capacity is usually priced according to CEUs or m2 occupied. On average, 100 m2 constitutes 1% of the total dayrate paid to the vessel operator. LATTICE carried out a case for 7,600 CEU capacity PCTC, implementing an optimized LPV instead of a cylinder, without compromising total m3 of the fuel tank. The space consequently freed resulted in equivalent 95 CEUs saved comparatively (equal to 600m2), thus constituting 6% of the dayrate. The vessel conducted 6 roundtrips per annum (12 trips ) with an average dayrate of USD 50,000, where the vessel spent 30 days average at sea. The freed space increases the ship’s annual revenue generating capacity with an additional USD 1,080,000. Over vessel lifetime (20y), revenues are increased by total USD 21,600,000. For car owners or operators of car carrier fleets, LATTICE delivers a substantial revenue enhancing opportunity and competitive edge that cannot be ignored in today’s tightly contested vehicle freight market.

Contact us to see how we can improve your fuel tank performance.

Flexible fuel tank solutions designed to ensure desired sailing range whilst minimizing impact on most valuable space – for instance lower decks dedicated to high value cargo.

Optimize your fuel tank configuration with LPV to ensure the most compact and efficient configuration whilst maintaining volumetric fuel capacity.

Within allocated holding space to increase vessel range, operational flexibility, and minimize downtime.

LPV tanks can be designed to accommodate LNG now and for switching to zero-emission fuel such as ammonia in the future.

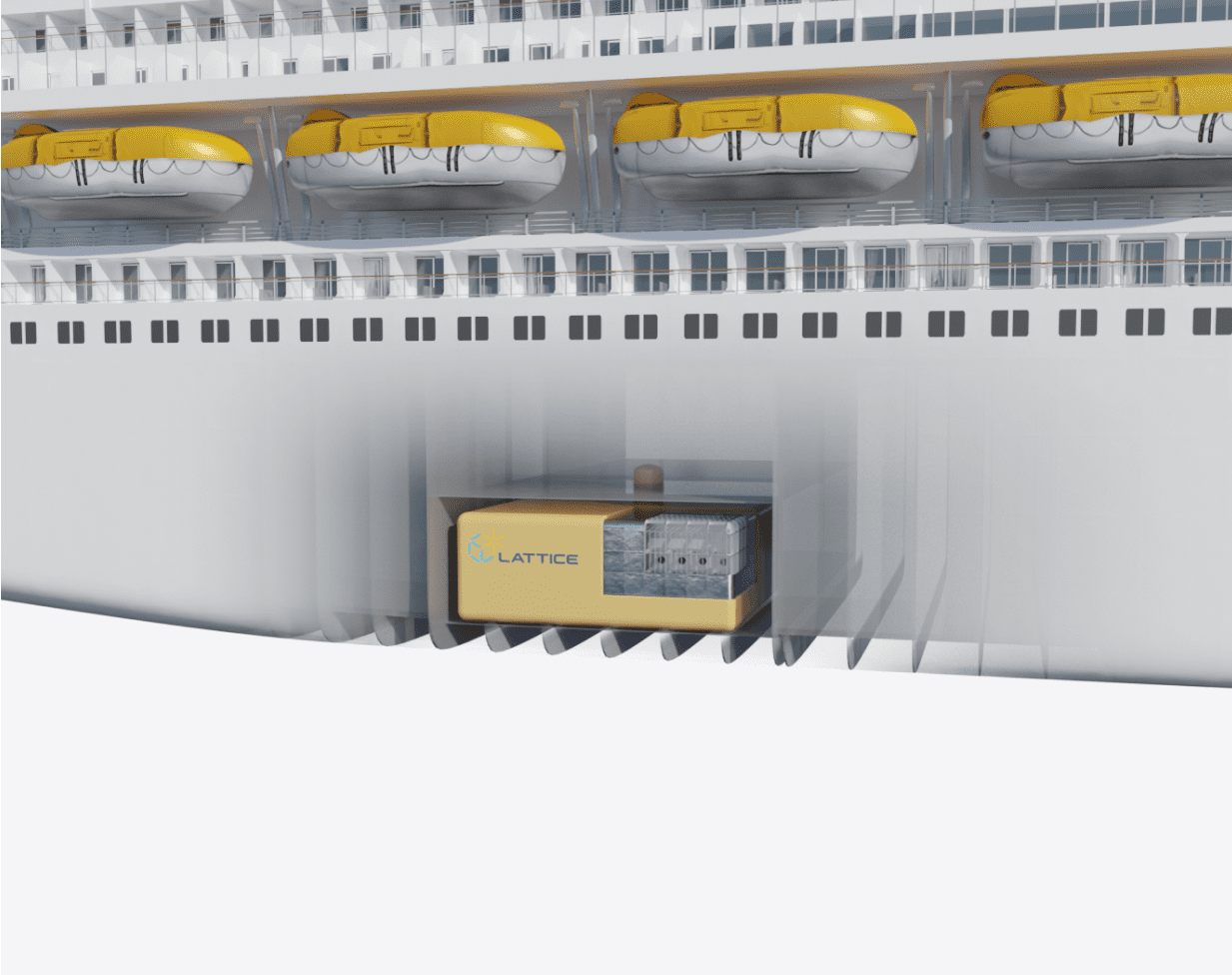

The cruise and ROPAX industry has made significant investments in the development of green technologies and practices, such as sustainable marine fuels, seeking to speed up the transition towards cleaner energy. However, several of these lower emission fuels require additional storage capacity to maintain the vessel’s range and operability, which in turn could have a significant impact on the revenue generating capacity of the ship.

A rapidly increasing number of cruise and ROPAX vessels are now running on LNG. More and more operators are looking to either LNG as a transition fuel, or to ammonia, or even hydrogen, to meet the future demands in emission reductions. All these options have significantly lower comparative energy density to that of MGO, which necessitates greater relative volumetric capacity fuel tanks for operating vessels over the same distances as before. Large size cruise and ROPAX vessels typically have 500-3,000 m3 LNG fuel tanks, thus impacting valuable space that would otherwise be used for payload. Further, fuel tanks can affect space availability potentially over multiple decks within the ship.

LATTICE offers cruise and ferry fleet owners the opportunity to enhance and optimize the fuel tank design for their vessels in every dimension, thereby minimizing, if not eliminating, the impact of the fuel tank on decks dedicated to higher value payload. Tailor-made box-shaped LPV solutions can be integrated effectively into new vessel designs or adapted optimally to existing ship architecture, either as newbuild project or even retrofit.

Contact us to see how we can improve your fuel tank performance.

Flexible fuel tank solutions designed to ensure desired sailing range whilst minimizing impact on most valuable space.

Optimize your fuel tank configuration with LPV to ensure the most compact and efficient configuration whilst maintaining volumetric fuel capacity.

Within allocated holding space to increase vessel range, operational flexibility, and minimize downtime.

LPV tanks can be designed to accommodate LNG now and for switching to zero-emission fuel such as ammonia in the future.

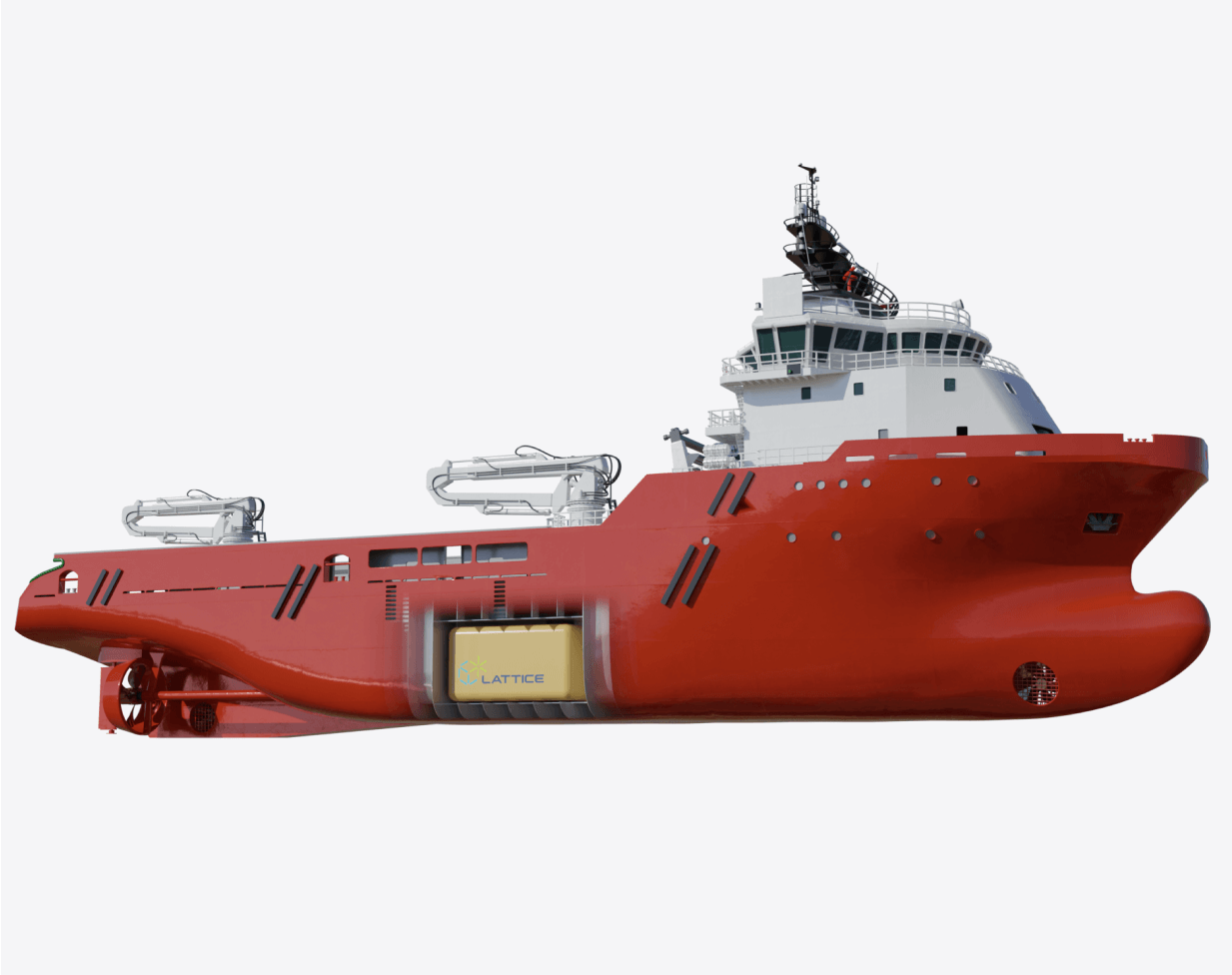

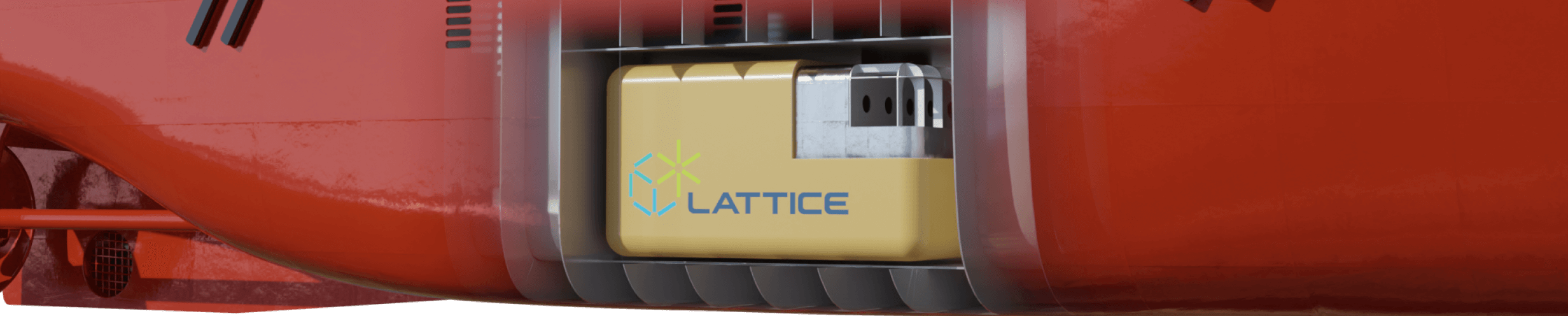

With the oil and gas industry being forced towards a greener profile, the pressure is on OSV (AHTS and PSV) operators to meet the increased demands for higher efficiency and low- to zero emission operations, both in port and offshore. The ability to maximize the fuel carrying capacity of the vessel – for LNG, and especially for lower energy density fuels like ammonia – and thereby increase operational range and duration, will have a direct impact on these parameters.

The OSVs are the workhorses of the offshore industry, playing a vital role in the operation of both oil and gas installations, wind farms, and other offshore assets. Currently, the active global OSV fleet comprises about 3,100 vessels, of which only 36 are purely LNG fuelled and 16 are ammonia ready. In these relatively small vessels, with very limited deck or hull space for type-C fuel tanks, switching from conventional fossil fuels to lower- or zero carbon fuels like LNG or ammonia without sacrificing crucial payload capacity or operational range and flexibility is a major challenge.

LATTICE offers owners the opportunity to enhance and optimize the fuel tank design for their vessels in every dimension, thereby minimizing, if not eliminating, the impact of the fuel tank on spaces dedicated to higher value cargo. Tailor-made box-shaped LPV solutions can be integrated effectively into new vessel designs or adapted optimally to existing ship architecture, for both newbuild and retrofit projects.

PSV: LPV vs. Cylinder dual-purpose fuel tank

A PSV’s operational efficiency and flexibility is measured based on its number of days in the field, servicing offshore assets or performing subsea operations. With the switch to lower- to zero carbon fuels, operational range and duration is becoming even more important to maintain a viable and attractive business case.

LATTICE carried out a case for a PSV with two dual-purpose fuel tanks, implementing optimized LPV tanks instead of cylinders, increasing the total fuel tank volume by almost 100% within the same tank hold space. The near doubling of fuel capacity resulted in the vessel’s offshore rotation being increased from 2 to 4 weeks, with corresponding required port calls being reduced from 24 to 12 per year. With an average duration of 3 days per port call (1 day sailing to shore, 1 day in port, 1 day sailing to field) and an average vessel day rate of USD 20,000, an increase in the PSV’s annual revenue of USD 720,000 was achieved. Over the vessel lifetime (20y), revenues were increased by total USD 14,400,000. For PSV owners or operators, LATTICE delivers a substantial revenue enhancing opportunity and competitive edge that cannot be ignored in today’s competitive and highly sustainability focused offshore market.

Contact us to see how we can improve your fuel tank performance.

Flexible fuel tank solutions designed to ensure desired sailing range whilst minimizing impact on most valuable space – for instance high value cargo holds.

Optimize your fuel tank configuration with LPV to ensure the most compact and efficient configuration whilst maintaining volumetric fuel capacity.

Within allocated holding space to increase vessel range, operational flexibility, and minimize downtime whilst maintaining the original payload capacity.

LPV tanks can be designed to accommodate LNG now and for switching to zero-emission fuel such as ammonia, methanol or even liquid hydrogen in the future.

Approved by ASME, all major Classification Societies, US Coast Guard