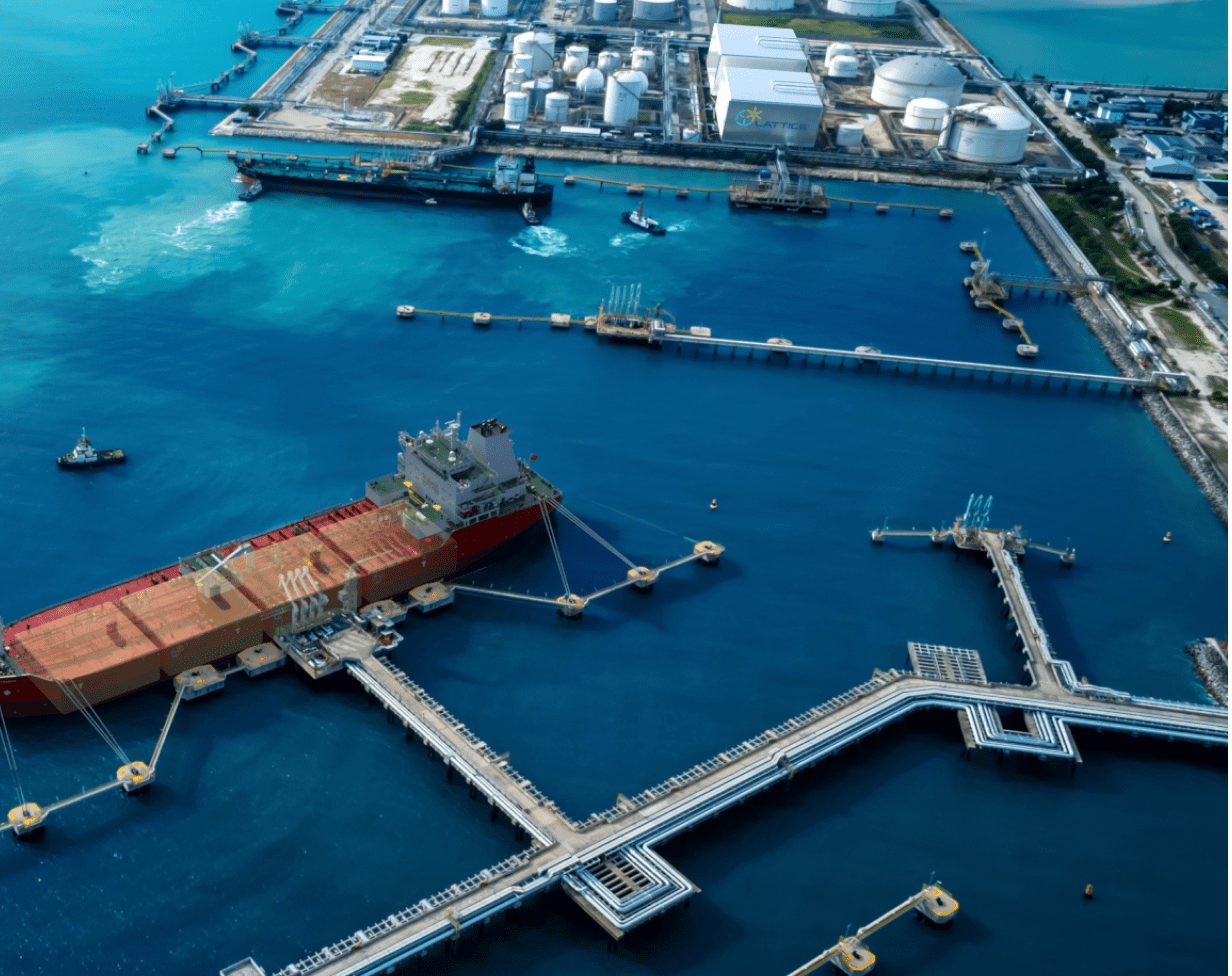

Onshore terminals act as storage hubs for fossil fuels, chemicals and other energy carriers, providing a crucial link between long-distance shipping and onshore local distribution. As the global economy is transitioning more and more towards low- or zero-carbon energy solutions, with CCS playing an important role in this transition, onshore terminals need to cater to large-scale intermediate storage of pressurized liquefied gases such as LCO2.

Space constraints due to existing infrastructure and limited available area is one of the main obstacles encountered at onshore terminals. A highly condensed terminal layout demands space-efficient storage solutions in order to maximize capacity for new commodities, such as LCO2, and the LPV’s design flexibility can cater to exactly this. Another common issue is the ground conditions and the related load bearing capacity. Conventional cylindrical tanks are typically installed in a vertical configuration to minimize footprint; however, this concentrates a lot of ground force in a small area. With the LPV, the storage tank size can be scaled up to both reduce the number of tanks required, providing a smaller overall footprint than a battery of cylinders, while also expanding the vertical supports’ footprint and reducing the ground forces per square meter. This will reduce, and in some cases eliminate, the need for time-consuming and expensive piling and civil works activities, further strengthening the viability of the business case.

The LPV offers terminal owners and operators the opportunity to optimize the space utilization within the existing terminal area without compromising on the most financially suitable storage capacity. The flexible LPV design can be tailored to fit any space or confinement, enabling a more compact and cost-efficient storage solution. The LPV’s scalability also allows for a reduced number of storage tanks, thereby reducing number of interfaces, pipe grids, auxiliary equipment, etc. – all of which provide higher flexibility and reduced cost.

Contact us to see how we can improve your fuel tank performance.

The tank design is capable of handling pressure ratings of 30+ barg and temperature ratings from -253 to +45 degC, offering terminal owners full flexibility.

Optimize your storage tank configuration with LPV to ensure the most compact and efficient solution, saving both CAPEX and OPEX, whilst maintaining volumetric capacity.

Within existing spaces to increase storage capacity and increase revenue streams.

The free-shape, free-size LPV design allows for limitless scalability and reduced number of tanks and related equipment and systems, enabling economies of scale and bringing down cost per m3 stored.

Approved by ASME, all major Classification Societies, US Coast Guard